In the hyper-competitive landscape of semiconductor manufacturing, where 3nm and beyond processes dominate and wafer yield margins are measured in millions of dollars, the quest for materials that balance ultra-high precision, contamination control, and operational efficiency has never been more critical. Semiconductor cleaning lines, the unsung heroes of chip fabrication responsible for eliminating sub-micron particles, metallic contaminants, and organic residues have long relied on traditional materials like stainless steel and quartz, which often fall short of modern process demands.

Today, precision machined aluminum alloys, including custom aluminum plates, aluminum bars, and aluminum tubes, are emerging as a transformative force, rewriting the rules of cleanroom performance and proving that this versatile material is far more than a cost effective alternative, it’s a strategic upgrade that drives measurable improvements in yield, reliability, and sustainability.

The semiconductor cleaning process, whether wet bench etching or vacuum plasma cleaning, imposes extreme conditions on equipment components: corrosive chemical baths (including hydrofluoric acid and peroxide based etchants), rapid thermal cycling, ultra-high vacuum (UHV) requirements, and zero tolerance for particle generation. For decades, stainless steel was the material of choice for critical components like reaction chambers, wafer carriers, and fluid delivery manifolds, valued for its corrosion resistance but burdened by inherent limitations. Its high density increases equipment weight, complicating robotic handling systems, while its poor thermal conductivity leads to uneven temperature distribution, a fatal flaw in processes where ±0.5°C uniformity is non-negotiable. Quartz, meanwhile, offers excellent chemical inertness but lacks mechanical strength, making it prone to breakage during high-volume production.

Aluminum alloys, when precision machined to semiconductor grade specifications, address these pain points with a unique combination of material properties that align perfectly with cleaning line requirements. High purity aluminum alloys such as 6061-T6 and 5083 have become industry staples, thanks to their exceptional strength-to-weight ratio, delivering mechanical performance comparable to stainless steel at 30% of the density. This lightweight advantage is amplified when using custom aluminum plates for chamber bases and structural frames, aluminum bars for precision actuator components, and aluminum tubes for fluid delivery systems, all of which reduce overall equipment weight by up to 40%. The result translates to significant operational benefits: robotic arms and wafer handling systems experience reduced wear, lowering maintenance costs by up to 25%, while easier equipment reconfiguration supports the fast product iterations demanded by the semiconductor industry.

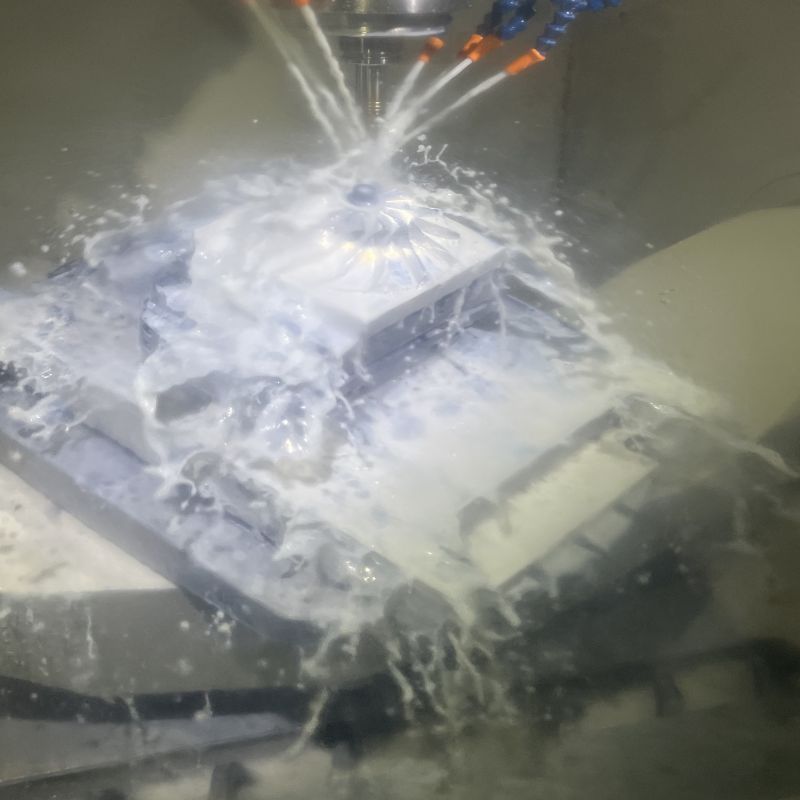

Precision machining is the key to unlocking aluminum’s full potential in cleanroom environments, and our specialized aluminum machining services are tailored to meet the strictest semiconductor standards. Advanced CNC machining techniques, including deep-hole drilling with L/D ratios of 30:1 and ultra-precision milling, create aluminum components with dimensional tolerances as tight as ±0.002mm, meeting the SEMI F72 standard for contamination control and ensuring seamless integration with existing cleaning line equipment. The smooth surface finish achieved through electropolishing (Ra < 0.2μm) minimizes particle adhesion, a critical factor in maintaining particle counts below 20 @ 0.12μm, the benchmark for advanced wafer cleaning. Unlike stainless steel, which requires complex welding that creates potential leak points, aluminum tubes and aluminum plates can be fabricated into one-piece components through precision machiningeli, minating seams and reducing helium leak rates to below 10⁻⁹ mbar·L/s, essential for UHV plasma cleaning chambers.

Corrosion resistance, once a perceived weakness of aluminum, has been overcome through specialized surface treatments and alloy selection for our aluminum products. Anodized aluminum plates with a 25μm+ oxide layer exhibit 10 times greater resistance to CF₄/O₂ plasma exposure than untreated metals, making them ideal for plasma cleaning chamber liners. For wet bench applications, aluminum tubes and manifolds treated with AMS 2772-specification coatings withstand prolonged exposure to buffered oxide etchants (BOE) and hydrofluoric acid (HF) solutions, outperforming traditional materials in long-term durability tests. A case study from a leading wafer foundry demonstrated that replacing stainless steel wet bench manifolds with anodized aluminum tube assemblies reduced corrosion-related downtime by 40% over a two-year period, while cutting material costs by 35%.

Thermal management is another area where aluminum excels, directly impacting cleaning line efficiency and wafer quality. With a thermal conductivity of approximately 150 W/m·K, far superior to stainless steelal, uminum plates used as cooling substrates dissipate heat evenly, preventing thermal deformation that can compromise wafer alignment. Precision machined aluminum bar heat sinks, integrated into plasma generator components, maintain stable operating temperatures even during continuous production runs. Additionally, aluminum tube micro channels, embedded within wet bench bath walls, enable precise temperature control of chemical solutions, critical for controlling exothermic etching reactions and reducing total thickness variation (TTV) to below 3%. This thermal stability translates to tangible yield improvements: a 2024 industry benchmark study found that aluminum equipped cleaning lines increased 3nm wafer yields by 7%~9% compared to stainless steel systems, equating to millions in additional revenue for high-volume fabs.

Beyond performance, aluminum offers compelling sustainability and cost advantages that resonate with modern semiconductor manufacturers. The material’s high recyclability aligns with the industry’s push for greener manufacturing, while its lower density reduces transportation costs for aluminum plates, aluminum bars, and aluminum tubes. Machining aluminum requires 35% less energy than stainless steel, and material costs are approximately 40% lower, without sacrificing performance. For mid sized fabs looking to scale production without massive capital investment, aluminum based cleaning line upgrades, leveraging precision machined aluminum components, provide a cost effective path to meeting advanced process requirements.

As semiconductor processes continue to shrink and cleaning processes become more demanding, aluminum’s role in cleaning line innovation is set to grow. The development of high-strength aluminum alloys like 7075-T651, with enhanced mechanical properties for structural aluminum bar components, and the integration of micro machined aluminum plates into microfluidic cleaning systems are expanding the material’s applications. With its unique combination of precision, performance, and cost-efficiency, aluminum is no longer just an alternative, it’s the material of choice for semiconductor manufacturers looking to gain a competitive edge in a faste volving industry. The rise of aluminum in semiconductor cleaning lines isn’t just a material shift; it’s a paradigm change that proves innovation often comes from reimagining the fundamentals.

Post time: Jan-22-2026