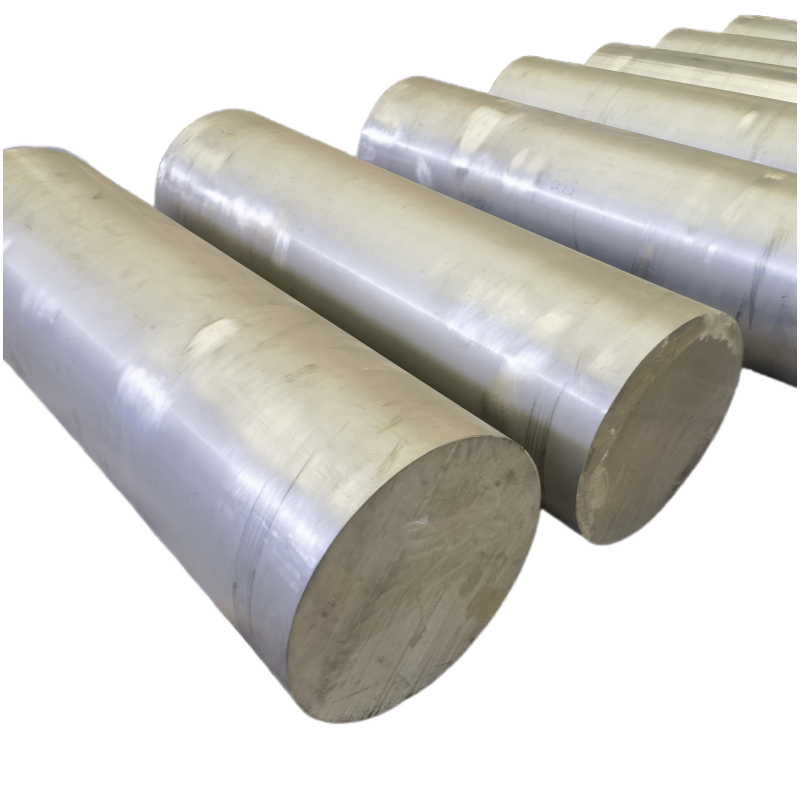

In the realm of high-performance aluminum alloys, 7075 T652 forged aluminum bars stand out as a benchmark for strength, durability, and dimensional stability, making them the material of choice for industries where “lightweight yet robust” is not just a requirement, but a critical driver of operational efficiency. Unlike standard aluminum grades, 7075 T652 undergoes a precision hot forging process paired with the T652 heat treatment (solution annealing, quenching, and artificial aging at controlled temperatures), resulting in a material that eliminates internal defects, refines grain structure, and unlocks exceptional mechanical properties. For manufacturers in aerospace, automotive, and precision engineering, this alloy bridges the gap between raw material reliability and end-product performance, addressing core pain points such as component failure under high stress, weight-related energy inefficiencies, and strict industry compliance standards.

1. Chemical Composition: The Foundation of Superior Performance

The exceptional characteristics of 7075 T652 forged aluminum bars are rooted in its carefully calibrated chemical composition, where each alloying element plays a targeted role in enhancing strength, corrosion resistance, and processability. As a member of the 7000 series aluminum alloys (zinc-magnesium-copper alloys), its formulation adheres to strict ASTM B211 and EN 573-3 standards, ensuring consistency across every batch, a non-negotiable factor for industries with zero tolerance for material variability.

The major alloying elements are the backbone of its performance:

- Zinc (Zn): 5.1%~6.1%. The primary strength-enhancing element. Zinc forms intermetallic compounds (e.g., MgZn₂) during heat treatment, enabling the alloy’s signature high tensile strength through precipitation hardening.

- Magnesium (Mg): 2.1%~2.9%. Works synergistically with zinc to amplify precipitation hardening. By promoting the formation of fine, uniform precipitates in the aluminum matrix, magnesium boosts both strength and fatigue resistance, critical for components subjected to repeated loads.

- Copper (Cu): 1.2%~2.0%. Enhances not only strength but also machinability and stress corrosion cracking (SCC) resistance. Copper modifies the structure of intermetallic phases, reducing brittleness and improving the alloy’s response to precision machining operations like milling and drilling.

Trace elements and impurities are tightly controlled to avoid performance degradation:

- Chromium (Cr): 0.18%~0.28%. Acts as a grain refiner, limiting grain growth during forging and heat treatment. This results in a more uniform microstructure, which translates to consistent mechanical properties across the entire bar.

- Iron (Fe) & Silicon (Si): ≤0.50% each. Minimized as impurities, as excessive levels can form coarse intermetallic particles (e.g., Al₃Fe) that weaken the alloy and reduce ductility.

- Manganese (Mn), Titanium (Ti), & Other Elements: ≤0.30% total. Added in small quantities to further stabilize the matrix and improve thermal stability, ensuring the alloy retains its properties even in moderate-temperature environments.

2. Comprehensive Performance: Where Strength Meets Versatility

7075 T652 forged aluminum bars’ performance profile is a masterclass in balancing conflicting material demands, offering the high strength of steel, the lightweight advantage of aluminum, and the processability of more malleable alloys. Its performance is not just “impressive” in lab tests; it is engineered to withstand real-world stressors, from extreme pressure in aerospace components to constant vibration in automotive parts.

Mechanical Performance: Industry-Leading Strength

After the T652 heat treatment (solutionized at 460°C~480°C, quenched in water, and artificially aged at 120°C~130°C for 24 hours), the alloy achieves mechanical properties that outperform most non-ferrous metals:

- Tensile Strength (σb): ≥510 MPa. Exceeds that of many low-carbon steels while weighing only 1/3 as much, making it ideal for weight-sensitive structures.

- Yield Strength (σ0.2): ≥470 MPa. Ensures components resist permanent deformation even under high static or dynamic loads, such as aircraft landing gear or industrial machinery shafts.

- Elongation at Break (δ): ≥8% A critical metric for durability; unlike brittle high strength alloys, 7075 T652 retains enough ductility to absorb impact energy, reducing the risk of sudden failure.

- Fatigue Strength (10⁷ cycles): ≥150 MPa Essential for components subjected to repeated stress, such as automotive suspension parts or rotating shafts, where fatigue cracking is a common failure mode.

Physical & Environmental Performance

Beyond mechanical strength, the alloy’s physical properties enhance its practicality in diverse applications:

- Density: 2.81 g/cm³ 35% lighter than steel (7.85 g/cm³) and 10% lighter than titanium (4.51 g/cm³), directly reducing fuel consumption in automotive/aerospace applications and easing installation in heavy machinery.

- Thermal Conductivity: 130 W/(m·K) Lower than pure aluminum (237 W/(m·K)) but sufficient for heat dissipation in components like electronic enclosures or engine parts, preventing overheating.

- Corrosion Resistance: Moderate to High. When paired with surface treatments (e.g., anodizing, chromate conversion), it resists oxidation and chemical attack in harsh environments, such as marine or industrial settings. Unlike untreated 7075, the T652 temper minimizes SCC, a key advantage over other high-strength aluminum grades.

Processing Performance: Adaptable to Precision Manufacturing

Forging is not just a shaping process for 7075 T652. It is a way to optimize performance. The hot forging process (typically at 350–450°C) aligns the alloy’s grain structure with the direction of stress, enhancing strength in critical load-bearing axes. Additionally:

- Machinability: Excellent. The copper content reduces tool wear, allowing for tight tolerances (up to ±0.005 mm) in precision machining operations. This is critical for components like hydraulic valves or aerospace fasteners, where dimensional accuracy is non-negotiable.

- Weldability: Controlled. While not as weldable as 6061 aluminum, it can be welded using specialized techniques (e.g., friction stir welding) with pre&post-weld heat treatment, expanding its use in large, welded structures.

- Formability: Moderate. Forged bars retain enough ductility for secondary forming processes like bending or extrusion, making them adaptable to custom component designs.

3. Application Scope: Powering High Demand Industries

7075 T652 forged aluminum bars’ unique combination of strength, lightweight, and processability makes them indispensable in industries where failure is costly, and efficiency is paramount. Below are its key application areas, each tied directly to its performance advantages:

Aerospace & Defense

The aerospace industry is the largest adopter of 7075 T652, thanks to its compliance with aerospace standards (e.g., AMS 4343). Key applications include:

- Aircraft Structural Components: Wing spars, fuselage frames, and landing gear components where its high strength-to-weight ratio reduces aircraft weight (and thus fuel costs) while meeting FAA safety requirements.

- Defense Equipment: Armor plates for military vehicles and structural parts for drones where its impact resistance and lightweight design enhance mobility without compromising protection.

Automotive (High-Performance & Electric Vehicles)

In the shift toward electric vehicles (EVs) and high-performance racing cars, weight reduction is critical for extending battery range and improving handling. 7075 T652 is used for:

- EV Powertrain Components: Motor shafts and battery enclosures where its strength protects sensitive electronics, and its lightweight design reduces the vehicle’s overall weight.

- Racing Car Parts: Suspension arms, steering knuckles, and brake calipers where its fatigue resistance withstands the extreme stress of high speed driving, and its machinability allows for aerodynamic, custom designs.

Industrial Machinery & Precision Engineering

For industrial equipment that operates under constant stress or requires tight tolerances, 7075 T652 delivers reliability:

- Heavy Machinery: Hydraulic cylinder rods and crane components where its high yield strength resists bending under heavy loads, and its corrosion resistance withstands outdoor or industrial environments.

- Precision Tools: Machine tool spindles and robotic arms where its dimensional stability (low thermal expansion coefficient: 23.6 μm/(m·K)) ensures consistent performance even during long production runs.

Marine & Offshore

While aluminum is not typically the first choice for marine applications, 7075 T652 (with proper surface treatment) excels in:

- Marine Hardware: Boat propeller shafts and rigging components where its lightweight design eases installation, and its corrosion resistance (when anodized) withstands saltwater exposure.

Partner with Us for Premium 7075 T652 Forged Aluminum Bars

We specialize in producing 7075 T652 forged aluminum bars that meet the strictest industry standards from ASTM to AMS. Our forging process uses state-of-the-art equipment to ensure uniform grain structure, and every batch undergoes rigorous testing (tensile testing, hardness testing, and chemical composition analysis) to guarantee performance consistency. Whether you need custom lengths, diameters, or surface treatments (anodizing, powder coating), our engineering team works with you to deliver solutions tailored to your application.

For aerospace, automotive, or industrial manufacturers seeking a high-strength, lightweight aluminum solution, 7075 T652 forged aluminum bars are the answer. Contact us today to request a technical datasheet

Post time: Nov-17-2025