Njengomboneleli okhokelayo wezinto ze-aluminium ze-premium kunyeukuchaneka kweenkonzo zomatshini ze-CNC, I-Shanghai Miandi Metal Products Co., Ltd. igxile ekuhambiseni ii-alloys ze-aluminiyam ezisebenza kakuhle ezilungiselelwe i-CNC yokusila, ukujika, kunye nokwenza. Nokuba ufuna izinto ezikhaphukhaphu ezinejiyometri entsonkothileyo okanye amacandelo anamandla aphezulu kumashishini afuna ngamandla, ubuchule bethu ekukhetheni i-alloy kunye noomatshini buqinisekisa ukuchaneka okungahambelaniyo kunye nokuthembeka.

1. Ii-Aluminiyam eziphambili ze-Aluminiyam ze-CNC Machining

CNC machining kufuna ialloys ukuba ulungelelaniso machinability, uzinzo dimensional, ukugqiba umphezulu, kunye neempawu mechanical. Apha ngezantsi kukho uluhlu olusetyenziswa kakhulu lwe-aluminium kunye neenzuzo zabo ezizodwa:

a. 6000 Series Aluminium (6061, 6063)

Ukubunjwa okuPhambili: I-Silicon (Si) kunye ne-magnesium (Mg) njengezinto eziphambili ze-alloying (umz., 6061: 0.6% Si, 1.0% Mg).

Ukucutshungulwa: Ukubunjwa kwe-chip egqwesileyo kunye nemikhosi ephantsi yokusika, ilungele ukusebenza kwe-CNC ye-high-speed.I-Smooth surface finish (Ra ≤ 1.6μm) ifikeleleke ngaphandle kokugqithiswa kwe-post-processing.

IiPropati zoomatshini: Amandla aphakathi (i-UTS: 260–310 MPa kwi-T6 temper), ukumelana ne-corrosion elungileyo, kunye ne-weldability.I-Heat-treatable (T4/T6 tempering) yokuqinisa ubulukhuni kunye nokuthembeka kwesakhiwo.

Usetyenziso oluqhelekileyo: Izibiyeli zeAerospace, izixhobo zemoto, iinxalenye zerobhothi, kunye ne-aluminiyam extrusions.

Kutheni Sikhetha Thina: Sinikezela nge-6061-T6 / T651 iiplate ze-aluminium / iintonga ezinokunyamezela okuqinileyo (± 0.01 mm), zilungele ukugaya i-CNC ephezulu.

b. 7000 Series Aluminium (7075)

Ukubunjwa okuPhambili: I-Zinc (Zn) njengomqinisekisi oyintloko, kunye ne-Mg kunye ne-Cu (umz., i-7075: 5.6% Zn, 2.5% Mg).

I-Machinability: Ubunzima obuphezulu kunoluhlu lwe-6000 ludinga izixhobo ze-carbide okanye ze-PCD, kodwa zibonelela ngokucokisekileyo ukusika ukuchaneka kweemilo eziyinkimbinkimbi.

IiPropati zoomatshini: Amandla aphezulu kakhulu (i-UTS: ukuya kuthi ga kwi-572 MPa kwi-T651 temper), eyenza ibe yomelele kuneentsimbi ezininzi ngelixa lihlala lilula.Ukumelana nokukhathala okuphezulu, okubalulekileyo kwi-aerospace kunye noxinzelelo oluphezulu lwezicelo zoshishino.

Usetyenziso oluqhelekileyo: Amalungu olwakhiwo lwenqwelomoya (umz., amacandelo ephiko), i-motorsport chassis, kunye nokungunda okuchanekileyo.

I-Advanteji yethu: Iintsimbi ze-aluminium zePremium 7075-T651 / iipleyiti ezine-annealing yokunciphisa uxinzelelo, ukunciphisa i-warpage eyenziwe ngoomatshini.

c. 2000 Series Aluminium (2024)

Ukuqulunqwa okuPhambili: I-Copper (Cu)-esekelwe kwi-Mg / Mn (umz., i-2024: 4.4% Cu, 1.5% Mg).

Ubucukubhede:Ubuchule bokuchwetheza (ingakumbi kwiindawo ezithintelweyo) kwi-CNC ukujika kunye nokugaya, nangona i-tenders harder (T8) ifuna izixhobo eziqinileyo.

IiPropati zoomatshini:Amandla aphezulu (i-UTS: 470–485 MPa kumsindo we-T351) kunye nokumelana nokudinwa okugqwesileyo.Ubushushu obunyangekayo bokuqina kokuqina kwizicelo zokuthwala umthwalo.

Usetyenziso oluqhelekileyo:Amaphiko eenqwelomoya, iinxalenye zegiya zokumisa, kunye nezinto ezinomatshini osebenza kakhulu.

d. 5000 Series Aluminium (5052, 5083)

Ukubunjwa okuPhambili: I-Magnesium (Mg)-ecebileyo (umzekelo, i-5052: 2.5% Mg).

Ubuchule: Ithambile kunye ne-ductile, ilungeleI-CNC yokwenza kunye nokugoba ngaphandleukuqhekeka.Ukugqitywa komphezulu ogqwesileyo kumalungu okuhombisa okanye abuthathaka.

IiPropati zoomatshini:Amandla aphakathi anokuxhathisa umhlwa okungaqhelekanga (alungele imeko-bume yaselwandle okanye yangaphandle).Ayinyangekiyo ubushushu, kodwa ukuqina komsebenzi kwandisa ukuqina.

Usetyenziso oluqhelekileyo:Iiholi zamaphenyane, izixhobo zekhemikhali, kunye nezinto zokuhombisa ezenziwe ngoomatshini be-CNC.

Ukunikezelwa kwethu: iipleyiti ze-aluminium ze-2024-T351 eziqinisekisiweyo kwimigangatho ye-aerospace (umzekelo, i-AMS 4042).

2. I-CNC Machining Advantages of Aluminium Alloys

a. IiPropati zeMathiriyeli zilungiselelwe ukuchaneka

Uxinano olusezantsi: 2.7 g/cm³ (1/3 ubunzima bentsimbi), inciphisa inertia kumatshini okhawulezayo kunye neemveliso ezikhaphukhaphu ekupheleni.

I-Thermal Conductivity: Ukutshatyalaliswa kobushushu obuphezulu kunciphisa ukunxiba kwesixhobo kunye nokuguqulwa kwe-thermal ngexesha lokusika ngesantya esiphezulu.

Ukuziphatha kwe-Isotropic: Iipropathi zomatshini ezifanayo kuzo zonke iindlela, ziqinisekisa iziphumo zomatshini ezingaguqukiyo.

b. UkuSebenza ngoMatshini kunye nokusebenza kweendleko

Isantya esiphezulu sokusika: I-Aluminiyam ivumela amazinga okutya ukuya kwi-5000 mm / min (kuxhomekeke kwi-alloy), ukunciphisa amaxesha okujikeleza.

Ukuhambelana kweSixhobo: Iyahambelana ne-carbide, i-HSS, kunye nezixhobo ze-PCD, ezinikezela ukuguquguquka kokusebenza ngokukrakra kunye nokugqiba.

Ulawulo lweChip: I-Ductile alloys efana ne-6061 ivelisa iitshiphusi eziqhubekayo, ngelixa amabakala e-free-machining (umzekelo, i-6061 kunye ne-Pb / Bi eyongeziweyo) ivelisa iitshiphusi eziqhekekileyo zomatshini ozenzekelayo.

c. I-Post-Processing Flexibility

Ukugqitywa koMphezulu: I-Anodizing, i-powder coating, i-electroplating, okanye i-bead blasting ukunyusa i-aesthetics kunye nokuxhathisa ukubola.

Unyango loBubushushu: Ubushushu obuqhelekileyo (umzekelo, i-T6) ukufezekisa ubulukhuni obujoliswe kuko kunye nokukhululeka koxinzelelo emva komatshini.

3. Shanghai Miandi kaThixo CNC Machining Solutions for Aluminium

Siphucula amandla ethu okugqibela ukuya esiphelweni ukuguqula ialloys zealuminium zibe zizinto ezichanekileyo:

a. Ukubonelelwa ngezinto eziphathekayo

Uluhlu olupheleleyo lwe-aluminium alloy: 6061, 7075, 2024, 5052 kwiiplate, iintonga, iityhubhu, kunye ne-extrusions yesiko, ethathwe kwii-mills eziqinisekisiweyo.

Izinketho zobushushu: I-Annealed (O), i-solution-treated (T4), ubudala (T6), kunye nokunciphisa uxinzelelo (T651) ukuhlangabezana neemfuno zomatshini kunye nokusebenza.

b. Iinkonzo ezichanekileyo ze-CNC

Ubunakho boMatshini:

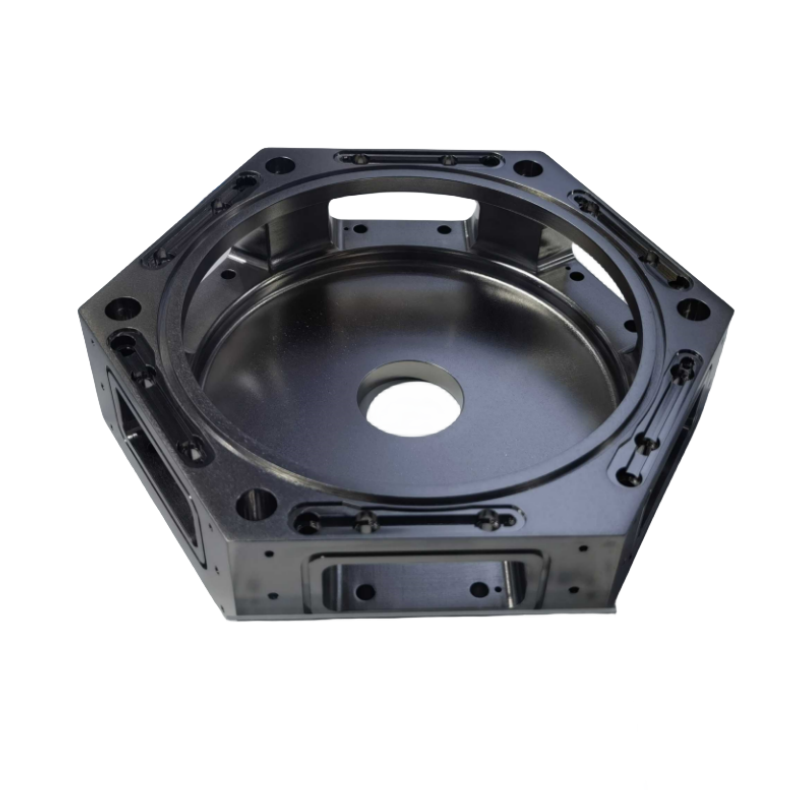

I-3/4/5-axis ye-CNC yokusila kwiijometri ezintsonkothileyo (umzekelo, izibiyeli ze-aerospace, izixhobo zonyango).

I-CNC yokujika i-shafts, i-hubs, kunye neengxenye ze-cylindrical (ukunyamezela: ± 0.005 mm).

I-Swiss machining ye-micro-precision components (ububanzi: 0.5-20 mm).

Inkqubo yoNcediso: Ukugaya, ukucofa, ukuthunga, ukubhula, kunye ne-EDM yeempawu ezinzima.

c. Ukuqinisekisa umgangatho

I-ISO 9001: I-2015 eqinisekisiweyo: Ukuhlolwa okungqongqo kwi-chemistry yezinto eziphathekayo, iipropathi zomatshini, kunye nokuchaneka komdanso (CMM / umlinganiselo we-optical).

Inkxaso ye-DFM: Ukudityaniswa kwasimahla koyilo-ngomatshini ukuze kwandiswe inxalenye yejometri ngexabiso kunye nokusebenza kakuhle.

d. Customization & Scalability

Iisampulu yebhetshi encinci ukuya kwimveliso ephezulu, kunye nokujika ngokukhawuleza (iintsuku ezi-7-10 zeprototypes).

Ukuthotyelwa kweshishini: Izixhobo eziqinisekisiweyo kwi-ASTM, AMS, GB, okanye imigangatho ye-ISO, kunye namaxwebhu anokulandeleka kubathengi be-aerospace kunye neemoto.

4. Kutheni Khetha iAluminiyam yeCNC Machining?

Ibhalansi yamandla obunzima: Ilungele usetyenziso apho uyilo olukhaphukhaphu lubalulekile (umzekelo, i-aerospace, i-drones).

Ixabiso Elisebenzayo: Iindleko ezisezantsi kunye neendleko zoomatshini kune-titanium okanye intsimbi, enokuphinda kusetyenziswe okugqwesileyo.

Inkululeko yoyilo: Iimilo ezintsonkothileyo, iindonga ezibhityileyo, kunye nokunyamezelana okuqinileyo okufikelelekayo ngezixhobo zale mihla ze-CNC.

Qhagamshelana neShanghai Miandi Namhlanje ukuze ilungiselelweCNC izisombululo machining usebenzisa premium aluminiyam alloys. Nokuba ufuna iprototype enye okanye izinto eziveliswe ngobuninzi, ubuchule bethu kukhetho lwealloyi, ukuchaneka komatshini, kunye nolawulo lomgangatho kuqinisekisa ukuba iprojekthi yakho iyaphumelela.

I-Shanghai Miandi Metal Products Co., Ltd. - Ukuchaneka kuyo yonke i-Cut.

Ixesha lokuposa: Jun-12-2025