Semutungamiri anotungamira we premium aluminium zvinhu uyechaiyo CNC machining masevhisi, Shanghai Miandi Metal Products Co., Ltd. inyanzvi mukuunza aruminiyamu alloys anokwenenzverwa akagadzirirwa CNC kugaya, kutendeuka, uye kugadzira. Kunyangwe iwe uchida zvinhu zvakareruka zvine akaomesesa geometries kana yakakwirira-simba zvikamu zveinoda maindasitiri, hunyanzvi hwedu mukusarudzwa kwealloy uye machining hunova nechokwadi chisingaenzaniswi nemazvo uye kuvimbika.

1. Key Aluminium Alloys yeCNC Machining

CNC machining inoda ma alloys anoyera machinability, dimensional kugadzikana, kupera kwepamusoro, uye michina zvivakwa. Pazasi pane anonyanya kushandiswa aluminium akatevedzana uye akasarudzika mabhenefiti:

a. 6000 Series Aluminium (6061, 6063)

Core Kuumbwa: Silicon (Si) uye magnesium (Mg) seyekutanga alloying zvinhu (semuenzaniso, 6061: 0.6% Si, 1.0% Mg).

Machinability: Yakanakisa chip kugadzirwa uye yakaderera kucheka masimba, yakanakira yakakwira-speed CNC mashandiro.Smooth surface finish (Ra ≤ 1.6μm) inogoneka pasina yakakura post-processing.

Mechanical Properties: Simba riri pakati nepakati (UTS: 260–310 MPa mukushatirwa kweT6), kusaita ngura yakanaka, uye kugoneka.Kupisa-kunorapwa (T4/T6 kudzikamisa) kwekuwedzera kuomarara uye kusimba kwechimiro.

Yakajairika maapplication: Aerospace mabhureki, zvinhu zvemotokari, marobhoti zvikamu, uye aluminium extrusions.

Sei Tisarudze Isu: Isu tinopa 6061-T6 / T651 aluminium mahwendefa / tsvimbo ine yakasimba dimensional tolerances (± 0.01 mm), yakagadzirira yakakwirira-chaiyo CNC milling.

b. 7000 Series Aluminium (7075)

Core Kuumbwa: Zinc (Zn) seyokutanga kusimbisa, ine Mg uye Cu (semuenzaniso, 7075: 5.6% Zn, 2.5% Mg).

Machinability: Kuoma kwepamusoro kudarika 6000 series kunoda carbide kana PCD zvishandiso, asi inopa kukwirira kwekucheka kwakanyatsonaka kune maumbirwo akaoma.

Mechanical Properties: Ultra-yakakwirira simba (UTS: inosvika 572 MPa muT651 kutsamwa), ichiita kuti ive yakasimba kudarika simbi dzakawanda ichiramba ichireruka.Kuramba kuneta kwepamusoro, kunokosha kune aerospace uye kushandiswa kwepamusoro-soro kwemaindasitiri.

Mashandiro akajairika: Zvimiro zvendege (semuenzaniso, zvikamu zvemapapiro), motorsport chassis, uye mold chaiyo.

Yedu Yakanakira: Yekutanga 7075-T651 aruminiyamu tsvimbo / mahwendefa ane kushushikana-kudzoreredzwa annealing, kuderedza machining-induced warpage.

c. 2000 Series Aluminium (2024)

Core Kuumbwa: Mhangura (Cu)-yakavakirwa neMg / Mn (semuenzaniso, 2024: 4.4% Cu, 1.5% Mg).

Machinability:Good machinability (kunyanya mumatunhu annealed) nokuda CNC kutendeuka uye kugaya, kunyange kuoma hasha (T8) zvinoda robust tooling.Kukwanisa kuwana zvakasimba tolerances nokuda aerospace-giredhi zvikamu.

Mechanical Properties:Simba repamusoro (UTS: 470–485 MPa muT351 hasha) uye yakanakisa kuneta kuramba.Kupisa-kunorapwa kune optimized kuoma mukutakura mitoro maapplication.

Yakajairika application: Ndege mapapiro spars, ekumhara giya zvikamu, uye yakakwirira-inoshanda mechanika zvinhu.

d. 5000 Series Aluminium (5052, 5083)

Core Kuumbwa: Magnesium (Mg) -hupfumi (semuenzaniso, 5052: 2.5% Mg).

Machinability: Yakapfava uye ductile, yakanakiraCNC kugadzira uye kukotama pasinacracking.Excellent surface finish for decoration or corrosion-sensitive parts.

Mechanical Properties:Simba riri pakati nepakati uye risingaiti ngura (yakanakira nzvimbo dzemugungwa kana dzekunze).Isingarapike pakupisa, asi kuomesa basa kunoita kuti kusimba.

Chimiro chekushandisa: Zvikepe zvezvikepe, makemikari emidziyo, uye CNC-yakagadzirwa nemidziyo yekushongedza.

Yedu Inopihwa: 2024-T351 aluminium mahwendefa akasimbiswa kune aerospace zviyero (semuenzaniso, AMS 4042).

2. CNC Machining Advantages yeAluminium Alloys

a. Material Properties Optimized for Precision

Low Density: 2.7 g/cm³ (1/3 huremu hwesimbi), kuderedza inertia yekukurumidza kugadzira uye kureruka kwekupedzisira zvigadzirwa.

Thermal Conductivity: Kupisa kupisa kwakanyanya kunoderedza kupfeka kwechishandiso uye deformation yekupisa panguva yekucheka kukuru.

Isotropic Behavior: Uniform mechanicha zvivakwa munzvimbo dzese, kuve nechokwadi chinopindirana machining mhedzisiro.

b. Machining Kubudirira & Mutengo-Kubudirira

High Cutting Speeds: Aluminium inobvumira kudya kwekudya kusvika ku5000 mm / min (zvichienderana nealloy), kuderedza nguva yekutenderera.

Kuenderana Kwechishandiso: Inoenderana necarbide, HSS, uye PCD maturusi, achipa kuchinjika kwekuita roughing uye kupedza mashandiro.

Chip Kudzora: Ductile alloys se6061 anogadzira anoenderera machipisi, nepo emahara-machining mamakisi (semuenzaniso, 6061 ine yakawedzerwa Pb/Bi) inoburitsa machipisi anogona kuputsika ekugadzira otomatiki.

c. Post-Processing Flexibility

Kupedzwa Kwepamusoro: Anodizing, poda coating, electroplating, kana bead blasting kuti uwedzere kunaka uye kusagadzikana kwekuora.

Kurapa Kupisa: Tsika yekupisa (semuenzaniso, T6) kuti uwane kuomarara kwechinangwa uye kuzorora kwekushushikana mushure mekugadzira.

3. Shanghai Miandi's CNC Machining Solutions yeAluminium

Wedzera kugona kwedu kwekupedzisira-kusvika-kumagumo kushandura aruminiyamu alloys kuita zvinhu chaizvo:

a. Material Supply

Yakazara yakatevedzana yealuminium alloy: 6061, 7075, 2024, 5052 mumaplateti, tsvimbo, machubhu, uye tsika extrusions, yakatorwa kubva kune dzakasimbiswa zvigayo.

Sarudzo dzeHasha: Yakanamirwa (O), mhinduro-yakarapwa (T4), yezera (T6), uye kunetseka-kurerutswa (T651) kuzadzisa machining uye kuita zvinodiwa.

b. Precision CNC Services

Machining Kugona:

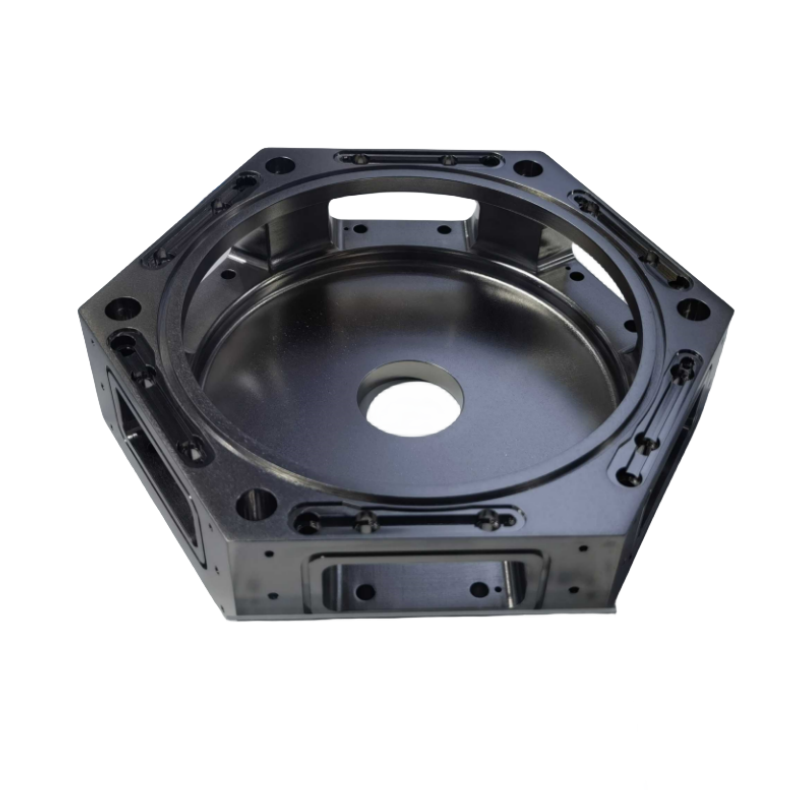

3/4/5-axis CNC kugaya kwema geometries akaoma (semuenzaniso, mabhuraketi emuchadenga, midziyo yekurapa).

CNC kutenderedza shafts, hubs, uye cylindrical zvikamu (kushivirira: ± 0.005 mm).

Swiss machining ye micro-precision components (diameter: 0.5-20 mm).

Maitiro ekubatsira: Kuchera, kubatika, tambo, broaching, uye EDM kune yakaoma maficha.

c. Hunhu Hwakanaka

ISO 9001: 2015 Certified: Kuongorora kwakasimba kwemakemikari zvinhu, mechanical zvivakwa, uye dimensional kurongeka (CMM/optical kuyerwa).

DFM Tsigiro: Yemahara dhizaini-ye-machining kubvunza kukwidziridza chikamu geometry yemutengo uye nekubudirira.

d. Customization & Scalability

Diki batch sampling kune yakakwira-vhoriyamu kugadzirwa, nekukurumidza kutendeuka (7-10 mazuva eprototypes).

Indasitiri kutevedzera: Zvishandiso zvakasimbiswa kune ASTM, AMS, GB, kana ISO zviyero, zvine zvinyorwa zvekuteedzera zveaerospace uye vatengi vemotokari.

4. Sei Sarudza Aluminium yeCNC Machining?

Huremu-Simba Chiyero: Yakanakira maapplication ayo akareruka dhizaini yakakosha (semuenzaniso, aerospace, drones).

Mutengo-Unoshanda: Yakaderera zvinhu uye machining mutengo pane titanium kana simbi, ine yakanakisa recyclability.

Dhizaini Rusununguko: Maumbirwo akaomarara, madziro matete, uye kushivirira kwakasimba kunowanikwa neazvino CNC michina.

Bata Shanghai Miandi Nhasi kuti igadzirisweCNC machining mhinduro uchishandisa premium aluminium alloys. Kunyangwe iwe uchida imwe chete prototype kana yakawanda-yakagadzirwa zvinhu, hunyanzvi hwedu mukusarudza alloy, machining nemazvo, uye kutonga kwemhando inoita kuti chirongwa chako chibudirire.

Shanghai Miandi Metal Products Co., Ltd. - Precision muCheka Chese.

Nguva yekutumira: Jun-12-2025