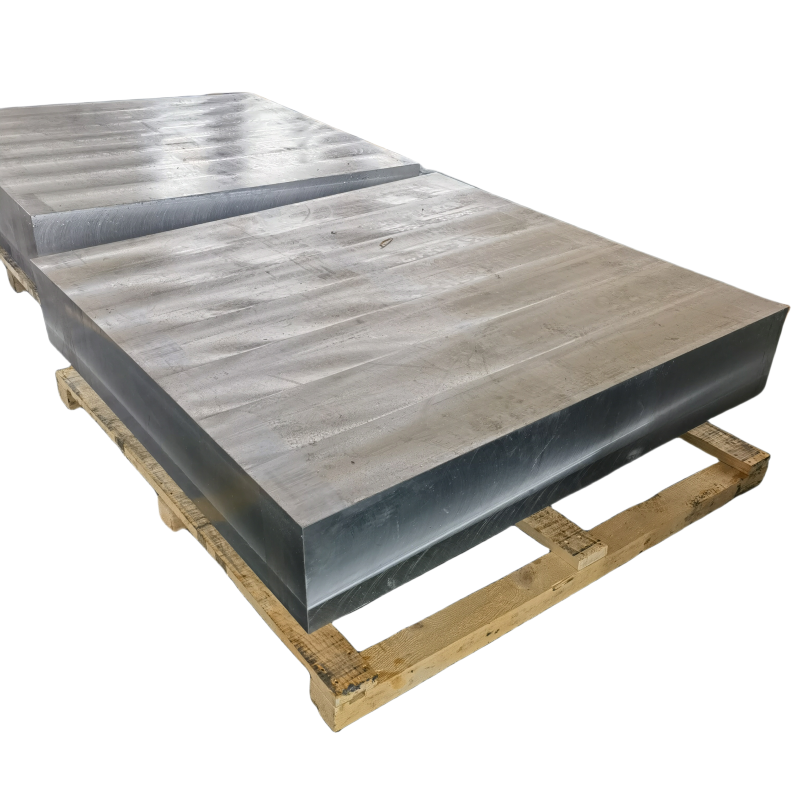

Kwiphulo elingapheliyo lokusebenza kakuhle kwesakhiwo, apho igram nganye kunye ne-megapascal nganye ibalulekile, i-aluminium alloy enye imele njengentshatsheli yamandla engenakuphikiswa: 7075. Xa le ngxube yenziwe ngokuchanekileyo kwaye ithomalaliswa kwi-T652, inkcazo efuna amanqanaba aphezulu okuhlala okuqinisekisiweyo, iguquka ibe yimpahla enamandla angaqhelekanga. Njengeqabane lakho elizinikeleyo lokubonelela kunye noomatshini, sibonisa olu lwazi lunzulu lobuchwephesha kwiIpleyiti ye-aluminiyam eyenziweyo ye-7075-T652, ichaza isizathu sokuba ihlala isisisombululo sobunjineli esibalulekileyo apho ukungaphumeleli kungelulo ukhetho

1. Ukwahlulahlula i-Alloy: Indlu enamandla yesinyithi eqhutywa yiZinc

I-7075 ikwi-ultra high strength 7000 series (Al-Zn-Mg-Cu). Iimpawu zayo ezimangalisayo azikho ngengozi kodwa zenziwe ngokusebenzisana okunamandla kwezinto eziphambili zokudibanisa kunye nenkqubo ye-thermomechanical elawulwa ngokungqongqo.

I-Zinc (Zn): 5.1%~6.1% – Ilitye lesiseko lamandla e-7075. I-Zinc, xa idibene ne-magnesium yenza i-dense, coherent η' (MgZn₂) kunye ne-T (AlZnMgCu) ezihlayo ngexesha lokwaluphala. Le ndlela yokuqinisa imvula inika umlinganiselo wamandla-kubunzima obungenakuthelekiswa nanto we-alloy.

I-Magnesium (Mg): 2.1%~2.9% – Isebenza ngokubambisana ne-zinc ukwenza izigaba zokuqala zokuqinisa. I-Magnesium ikwaphucula impendulo ye-alloy kunyango lobushushu besisombululo kunye nokumelana nokuqhekeka koxinzelelo xa isetyenzwa ngokufanelekileyo.

I-Copper (Cu): 1.2%~2.0% – Yonyusa amandla ngokuqinisa isisombululo esiqinileyo nangokuthatha inxaxheba ekwakhiweni kwe-precipitate. I-Copper iphucula kakhulu ukumelana nokudinwa kunye nokuqina, nangona itshintshana ekumelaneni nokugqwala ngokubanzi, nto leyo edinga ukhuseleko kwiindlela ezininzi.

I-Chromium (Cr): 0.18% ~ 0.28% – Isicoci esiphambili seengqolowa kunye nesithinteli sokuphinda kusetyenziswe iikristale. I-Chromium yenza ii-dispersoids ezincinci ezibamba imida yeengqolowa, nto leyo ebangela ukuba ulwakhiwo lweengqolowa lube luhle kwaye lufane ngakumbi, ingakumbi kwiimveliso ezenziwe ngobuchule eziphucula ukuqina kunye nokumelana nokuqhekeka koxinzelelo-ukubola (SCC).

Uyilo lwe-T652 Temper lucacile kwaye lufuna izinto ezininzi:

I-T6: Isisombululo sicocwa ngobushushu, sicinywe, kwaye sivundiswa ngokwenziwa ukuze sibe namandla aphezulu.

I-T652: Ibonisa ukuba izinto ezisetyenzisiweyo zifumene uxinzelelo olongezelelweyo olulawulwayo emva konyango lobushushu besisombululo (ngokolula okanye ukucinezela) nangaphambi kokuguga kokugqibela. Le nkqubo, edla ngokusetyenziswa kwiipleyiti ezinzima, inciphisa kakhulu uxinzelelo lokucima olushiyekileyo, ngaloo ndlela iphucula uzinzo olulinganayo ngexesha lokwenziwa kunye nokuphucula ukumelana nokuqhekeka koxinzelelo-umhlwa kwicala elifutshane elinqamlezileyo. Oku kwenza ipleyiti eyenziwe nge-7075-T652 ithembeke kakhulu kwiindawo ezintsonkothileyo nezichanekileyo.

2. Ukulinganisa Ubungakanani Bokubalasela: Iimpawu Zokulinganisa Iipropati Zoomatshini Nezomzimba

IIpleyiti eyenziwe ngomgunyathi ye-7075-T652Inika iprofayili yepropathi echaza umgangatho ophezulu wokusebenza kwe-aluminium, idibanisa iingenelo ze-isotropic zokubumba kunye nokuzinza kobushushu be-T652.

Iipropati eziqhelekileyo zoomatshini (Ngokwe-AMS 4136 / ASTM B209):

Amandla okuThatha aPhezulu (UTS): 78~83 ksi (538~572 MPa). La mandla angaqhelekanga akhuphisana nalawo eentsimbi ezininzi kwisinye kwisithathu sobunzima.

Amandla okuKhupha okuThamba (TYS): 69~73 ksi (476~503 MPa). Ibonisa umda ophezulu kakhulu wokuguqulwa okusisigxina phantsi komthwalo.

Ubude: 5% ~ 8% kwiisentimitha ezi-2. Nangona ukuguguleka kuphakathi, ukuqina (okulinganiswa bukuqina kokuqhekeka, i-K1C) kuphezulu kakhulu ngenxa yodidi lwayo lwamandla, inzuzo ethe ngqo yesakhiwo esenziwe ngobumba, esineengcongolo ezincinci.

Amandla okucheba: Malunga ne-48 ksi (331 MPa).

Amandla Okudinwa: Agqwesile. Umlinganiselo wayo wokunyamezela okuphezulu wenza ukuba ilungele ukusetyenziswa ngokuguquguqukayo, ukujikeleza umthwalo. Inkqubo yokubumba iphucula ubomi bokudinwa ngokudala ukuhamba kweenkozo okuqhubekayo kujikeleze iinxalenye zekhonkrithi.

Ubunzima: 150 HB (eqhelekileyo). Inika ukumelana okuhle kakhulu nokuguguleka nokukrweleka.

Ukuchaza iimpawu zomzimba nezokusebenza:

Ubuninzi: 0.101 lb/in³ (2.81 g/cm³).

Inzuzo Yokubumba: Inkqubo yokubumba ilungelelanisa isakhiwo sengqolowa, isusa ukubola, kwaye iphucula iimpawu zoomatshini kuzo zonke iindlela, inika ukuthembeka okuphezulu xa kuthelekiswa nepleyiti eqengqekileyo, ingakumbi kwiindawo ezixineneyo.

Ubuchule bokuSebenza: Inikwe inqanaba elithi “Kulungile.” Ingafakwa ngomatshini ukuze ikwazi ukumelana nobunzima obukhulu kunye nokugqitywa kakuhle komphezulu, kodwa ifuna ukuseta okuqinileyo, izixhobo ezibukhali, kunye nokutya/isantya esifanelekileyo ngenxa yamandla ayo aphezulu kunye nokurhawuzelela.

Ukumelana Nokugqwala: Ngokubanzi ayilunganga kwiimeko ezinganyangwanga, ingakumbi kwiindawo ezinetyuwa okanye ezineasidi. Ukufunxa (Uhlobo II okanye III), ukufunxa, okanye ukupeyinta kuyimfuneko ekukhuseleni ukugqwala kwiindawo ezininzi zenkonzo.

Ukumelana nokuqhekeka koxinzelelo-nokugqwala (SCC): Ubushushu be-T652, kunye nolawulo olufanelekileyo lwekhemistri ye-alloy (ingakumbi umxholo we-chromium), bubonelela ngokumelana kwe-SCC okuphuculweyo kakhulu xa kuthelekiswa nemeko ye-T6 yokuqala, into ebalulekileyo kwiinxalenye ze-aerospace zesakhiwo.

3. IiDomain zeSicelo: Zenzelwe Iindawo Ezinzima Kakhulu

Indibaniselwano eyahlukileyo yamandla aphezulu, ukumelana nokudinwa, kunye nokukhanya okuncinci kwenzaIpleyiti eyenziwe ngomgunyathi ye-7075-T652izinto ezikhethwayo kwiindawo apho ukusebenza kubaluleke kakhulu.

Inqwelo-moya kunye noKhuselo (Imarike Ephambili):

Izakhiwo ze-Airframe: Ii-wing spars, ii-bulkheads, ii-fuselage frames, kunye nezixhobo zokuxhasa izixhobo zokufika.

Inqwelo-moya yasemkhosini: Isetyenziswa kakhulu kwiifreyimu zeenqwelo-moya zeenqwelo-moya zokulwa, iimasti zehelikopta, kunye nezixhobo zokubeka izixhobo.

Uhambo lwasesibhakabhakeni: Izinto ezisetyenziswa kwisakhiwo sesathelayithi kunye nesithuthi sokuqalisa, apho ukusebenza kakuhle kobuninzi kubaluleke kakhulu.

Iimoto ezisebenza kakuhle kunye neMidlalo yeeMoto:

I-Chassis yeMoto yoKhuphiswano: Ii-suspension uprights (ii-knuckles), ii-control arms, kunye nee-gear housings kwi-Formula kunye ne-endurance racing.

Ukuphuculwa Kokusebenza: Iibrakethi ezixinezelekileyo kakhulu, ii-pedal assemblies, kunye nezixhobo ze-drivetrain zezithuthi ezijolise kumkhondo.

Oomatshini Boshishino Abaphambili:

Izixhobo Zokubumba: Kwizimbobo zeplastiki ezifuna ukupholishwa okuphezulu kunye nokumelana nokudinwa kubushushu.

Iirobhothi: Amalungu athwala umthwalo obalulekileyo kunye namalungu akwiirobhothi zoshishino ezikhawulezayo nezichanekileyo.

Ioyile neGesi: Izinto ezisetyenziswa kwizixhobo zokugrumba kunye nezixhobo apho kufuneka amandla aphezulu kunye nokuthembeka kwiindawo ezingezizo ezolwandle.

Izixhobo zemidlalo: Iifreyimu zebhayisekile ezikumgangatho ophezulu (zomdyarho), izixhobo zebhayisekile yentaba, kunye nezixhobo zokudubula iintolo ezikumgangatho ophezulu.

Ukusebenzisana kwiPeak Performance ne-7075-T652

UkucacisaIpleyiti ye-aluminiyam eyenziweyo ye-7075-T652kukuzibophelela ekusebenzeni okungapheliyo. Yinto ekumgangatho ophezulu kwizicelo zekhwalithi ephezulu, ifuna ubuchule ekuthengeni nasekuchweni. Ukuqonda isinyithi sayo, intsingiselo yobushushu bayo, kunye nemida yayo yokusetyenziswa ngundoqo ekuphunyezweni ngempumelelo.

Sidibanisa umsantsa phakathi kwesi sixhobo siphambili kunye nenxalenye yakho egqityiweyo. Sinikezela ngepleyiti eyenziwe nge-7075-T652 enokulandeleka, eqinisekisiweyo ngokupheleleyo, exhaswa lulwazi olunzulu lwesinyithi kunye nobuchule be-5-axis CNC machining obuxhotyiswe ukujongana nobunzima bayo. Siqinisekisa ukuba uyilo lwakho luxhamla kumandla apheleleyo ale alloy ikhethekileyo, ukusuka ekugqibeleleni kwezinto eziluhlaza ukuya kwinxalenye egqityiweyo ngokuchanekileyo.

Sicele umngeni ngeemfuno zakho zeprojekthi ezifuna kakhulu. Nxibelelana neengcali zethu zezixhobo zeenqwelo-moya nezokhuselo namhlanje ukuze ufumane ingcebiso yobugcisa, iziqinisekiso zezixhobo ezineenkcukacha, kunye nekowuteshini yokhuphiswano kwipleyiti ye-aluminium eyenziwe ngobumba ye-7075-T652.

Ixesha leposi: Disemba-30-2025