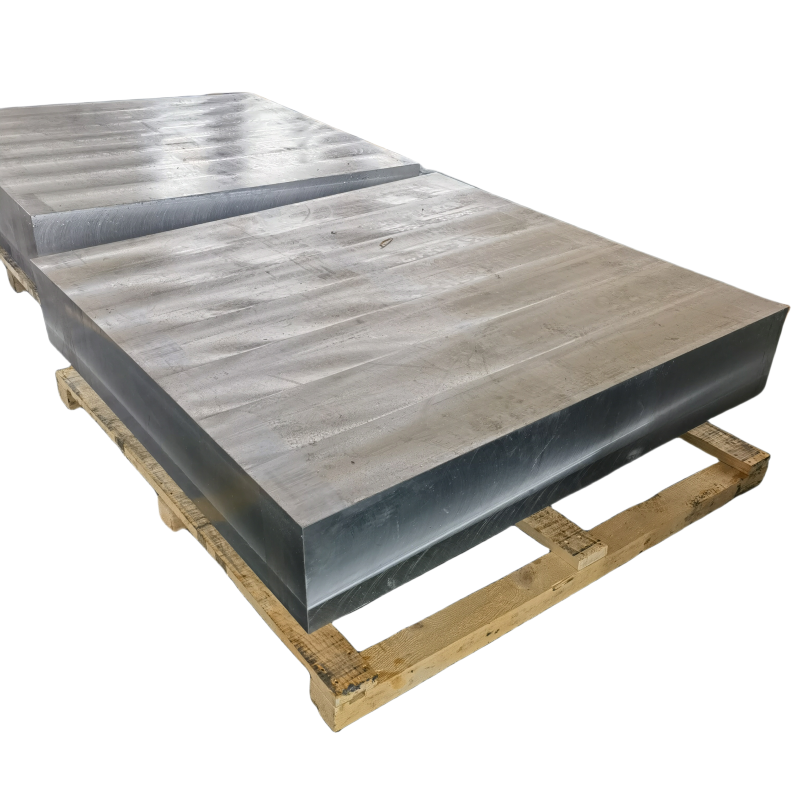

In the relentless pursuit of structural efficiency, where every gram and every megapascal counts, one aluminum alloy stands as the undisputed champion of strength: 7075. When this alloy is precision-forged and brought to temper T652, a specification demanding the highest levels of guaranteed consistency, it transforms into a material of extraordinary capability. As your dedicated supply and machining partner, we present this technical deep dive into 7075-T652 forged aluminum plate, detailing why it remains the critical engineering solution where failure is not an option

1. Deconstructing the Alloy: A Zinc-Driven Metallurgical Powerhouse

7075 belongs to the ultra high strength 7000 series (Al-Zn-Mg-Cu). Its formidable properties are not accidental but are engineered through a powerful synergy of primary alloying elements and a rigorously controlled thermomechanical process.

Zinc (Zn): 5.1%~6.1% – The cornerstone of 7075’s strength. Zinc, in combination with magnesium forms the dense, coherent η’ (MgZn₂) and T (AlZnMgCu) precipitates during aging. This precipitation hardening mechanism provides the alloy’s unparalleled strength-to-weight ratio.

Magnesium (Mg): 2.1%~2.9% – Works synergistically with zinc to create the primary strengthening phases. Magnesium also enhances the alloy’s response to solution heat treatment and stress corrosion cracking resistance when properly processed.

Copper (Cu): 1.2%~2.0% – Increases strength through solid solution strengthening and by participating in precipitate formation. Copper significantly enhances fatigue resistance and toughness, albeit with a trade-off in general corrosion resistance, which necessitates protective coatings in many applications.

Chromium (Cr): 0.18%~0.28% – A key grain refiner and recrystallization inhibitor. Chromium forms fine dispersoids that pin grain boundaries, resulting in a finer, more uniform grain structure, especially critical in forged products which improves toughness and resistance to stress-corrosion cracking (SCC).

The T652 Temper Designation is specific and demanding:

T6: Solution heat-treated, quenched, and artificially aged to peak strength.

T652: Indicates the material has undergone additional controlled stress relieving after solution heat treatment (by stretching or compressing) and before final aging. This process, often applied to heavy plates, dramatically reduces residual quenching stresses, thereby enhancing dimensional stability during machining and improving resistance to stress-corrosion cracking in the short transverse direction. This makes 7075-T652 forged plate exceptionally reliable for complex, high-precision components.

2. Quantifying Superiority: Mechanical & Physical Property Benchmarks

The 7075-T652 forged plate delivers a property profile that defines the upper echelon of aluminum performance, combining the isotropic benefits of forging with the stability of the T652 temper.

Typical Mechanical Properties (Per AMS 4136 / ASTM B209):

Ultimate Tensile Strength (UTS): 78~83 ksi (538~572 MPa). This exceptional strength rivals that of many steels at one-third the density.

Tensile Yield Strength (TYS): 69~73 ksi (476~503 MPa). Indicates an extremely high threshold for permanent deformation under load.

Elongation: 5%~8% in 2 inches. While ductility is moderate, the toughness (measured by fracture toughness, K1C) is remarkably high for its strength class, a direct benefit of the forged, fine-grain structure.

Shear Strength: Approximately 48 ksi (331 MPa).

Fatigue Strength: Excellent. Its high endurance limit makes it ideal for dynamic, load-cycling applications. The forging process further improves fatigue life by creating a continuous grain flow around part contours.

Hardness: 150 HB (typical). Provides excellent resistance to wear and abrasion.

Defining Physical & Operational Characteristics:

Density: 0.101 lb/in³ (2.81 g/cm³).

Forging Advantage: The forging process aligns the grain structure, eliminates porosity, and enhances mechanical properties in all directions, offering superior integrity compared to rolled plate, especially in thick sections.

Machinability: Rated “Fair.” It can be machined to very tight tolerances and excellent surface finishes, but requires rigid setups, sharp tools, and appropriate feeds/speeds due to its high strength and abrasiveness.

Corrosion Resistance: Generally poor in untreated conditions, particularly in saline or acidic environments. Anodizing (Type II or III), alodining, or painting is mandatory for corrosion protection in most service environments.

Stress-Corrosion Cracking (SCC) Resistance: The T652 temper, combined with proper alloy chemistry control (especially chromium content), provides significantly improved SCC resistance compared to the baseline T6 condition, a critical factor for structural aerospace components.

3. Application Domains: Engineered for the Most Demanding Environments

The unique combination of supreme strength, fatigue resistance, and lightweight makes 7075-T652 forged plate the material of choice in fields where performance is paramount.

Aerospace & Defense (Primary Market):

Airframe Structures: Wing spars, bulkheads, fuselage frames, and landing gear support components.

Military Aviation: Used extensively in fighter jet airframes, helicopter rotor masts, and weapon mounts.

Spaceflight: Satellite and launch vehicle structural components, where mass efficiency is critical.

High-Performance Automotive & Motorsport:

Competition Vehicle Chassis: Suspension uprights (knuckles), control arms, and gearbox housings in Formula and endurance racing.

Performance Upgrades: High-stress brackets, pedal assemblies, and drivetrain components for track-focused vehicles.

Advanced Industrial Machinery:

Mold Tooling: For plastic injection molds requiring high polishability and thermal fatigue resistance.

Robotics: Critical load bearing members and joints in high speed, high precision industrial robots.

Oil & Gas: Components for drilling equipment and tooling where high strength and reliability are required in non-marine sections.

Sporting Equipment: High-end bicycle frames (for racing), mountain bike components, and professional-grade archery equipment.

Partnering for Peak Performance with 7075-T652

Specifying 7075-T652 forged aluminum plate is a commitment to uncompromising performance. It is a premium material for premium applications, demanding expertise in both procurement and machining. Understanding its metallurgy, the meaning of its temper, and its application boundaries is key to successful implementation.

We bridge the gap between this advanced material and your finished component. We supply traceable, fully certified 7075-T652 forged plate, backed by profound metallurgical knowledge and state-of-the-art, 5-axis CNC machining capabilities equipped to handle its demanding nature. We ensure your designs benefit from the full potential of this exceptional alloy, from raw material integrity to precision-finished part.

Challenge us with your most demanding project requirements. Contact our aerospace and defense materials specialists today for a technical consultation, detailed material certifications, and a competitive quote on 7075-T652 forged aluminum plate.

Post time: Dec-30-2025